50 years of Gordopack – we protect what is important.

100 employees produce 24 hours a day, 7 days a week on 22 extrusion lines and 11 packaging machines with an in-house recycling plant

Today, we would like to use our expertise in plastic film production for something more. At Gordopack, we want to convince our customers with a clear set of values and strive to serve them in the best way possible. Our customers trust that our knowledge and innovative spirit to improve our product portfolio drives us at all times. Sustainability and the protection of our planet is a project close to our hearts. We continue to redesign our packaging more sustainably in order to further protect products and goods decades from now.

Since the beginning, we have been offering 100% recyclable films and process any film waste in our in-house recycling facility. Furthermore, we strive to reduce the amount of packaging per product and keep increasing the use of circular plastic in order to achieve our goal.

50 years of Gordopack – we protect what is important.

100 employees produce 24 hours a day, 7 days a week on 22 extrusion lines and 11 packaging machines with an in-house recycling plant

50 % share takeover by Jago Himperich

Successful BRC certification for highest food standard

Acquisition of a new recycling plant and completion of the machine park

Energy management ISO 50001 certification

50% spatial expansion of location at Lindlar

ISO 9001 quality management and ISO 14001 environmental management certification

Construction of the Indonesian subsidiary production PT Gordopack Flexible Packaging

Thamrat Vechviroon and Ralf Lehenbauer take over shares

Expansion of production and logistics halls

Extension of the extrusion and purchase of a recycling plant

Reconstruction of the company at the present location Schlosserstraße 31 in Lindlar

Fire destroys entire Location “Am Sägewerk”

Company expansion with manufacturing department

Günter Himperich takes over 100% of shares and headquarters moves from Rösrath to Lindlar

Foundation of Gordopack GmbH by Günter Himperich and M.C. Stefer

Easy to communicate with

and are thinking in possibilities

instead of problems.

Gordopack is a reliable and flexible

partner with high performance level,

no false promises.

Thamrat Vechviroon (Managing Director),

Günter Himperich (Company Founder),

Jago Himperich (Managing Director)

Extraordinary strength and high tear resistance characterise thermoplastic blown films.

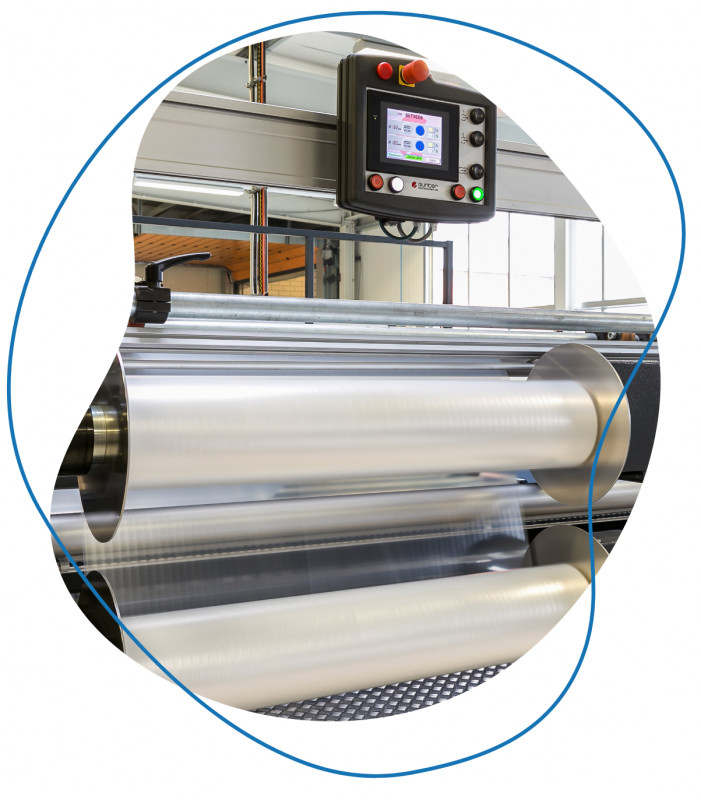

We manufacture our films exclusively on blown film lines of well-known German manufacturers. The quality of the equipment is crucial for a superior product.

We produce films that solely comprise one layer (so-called mono film) and films that are made of several layers (so-called coextruded films). With a coex blown film, it is possible to combine the positive properties of different raw materials into one film.

We manufacture our films ranging from widths of 100 mm to 2,100 mm on rolls. The perimeter can be as large as 5,600 mm on our extrusion lines. Typical processing materials are LDPE, LLDPE, MDPE and HDPE.

After the extrusion process, the film rolls are further processed into bags or sheets on our high quality converting machines.

With a variety of machine modules we generate a diverse product range. We distinguish between bag making machines, roll winders and tarpaulin winders.

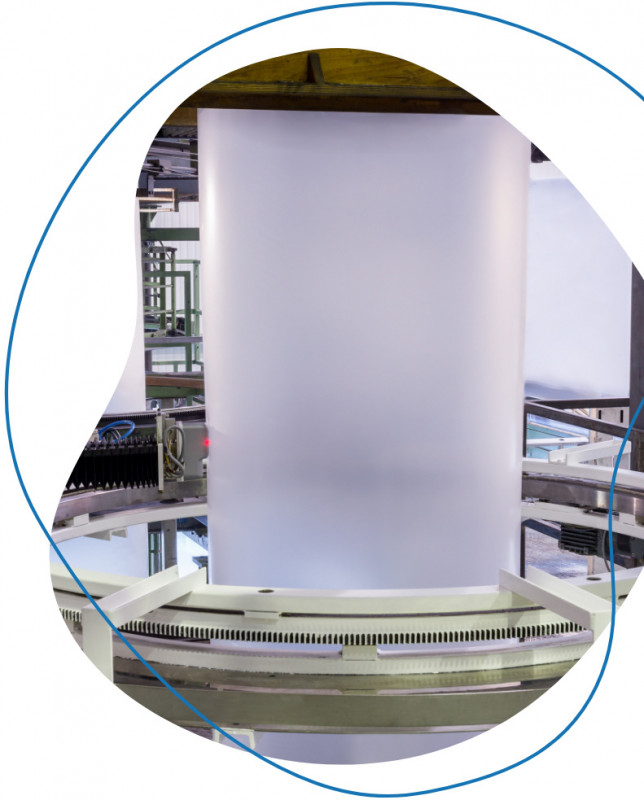

Before the delivery, our automated stretch film machine will wrap the product in order to ensure that the product is protected from any transportation damage or weather conditions.